Own development model for Integrated Management of Technological Innovation.

Development of virtual models to enhance the lifespan of components and capital equipment

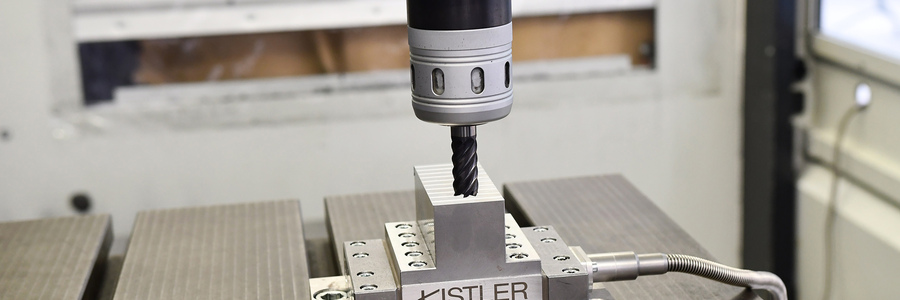

Digital twins are among the technologies that are revolutionising the capital equipment and energy component sectors. They are virtual replicas of physical entities, processes and systems that can be used to improve design and optimise operation and maintenance. A digital twin is developed using physical modelling technologies, starting from a profound knowledge of the functional behaviour and the failures of the physical device. The VIRTUAL project aims to go beyond the traditional digital twin concept to incorporate model prediction techniques based on physical models, experimental data and hybrid approaches.

The main objective is research into technologies and the generation of scientific-technological knowledge that will enable, in a future of no less than 5 years, the development of hybrid physical digital models (digital twins) of capital equipment and components that will make it possible to evaluate the behaviour of these systems during their life depending on the conditions of use, in such a way as to increase the reliability, extend the life of the assets and at the same time reduce their costs for companies.

The VIRTUAL project will eventually lead to gaining more information and will extend the analysis of failures and life to the systems used on capital equipment and components which can be exploited within the entire manufacturing value chain. The resulting digital twins will be the first step in accelerating the design and customization processes of physical assets, including specifications, design, optimization, service and maintenance, which is an absolute novel approach towards digital modelling processes.