Own development model for Integrated Management of Technological Innovation.

Development of virtual twins for identification and elimination of submicrometric marks in grinding

The fourth industrial revolution brings with it the increasing use of robotics, additive technologies and 3D printing. However, these new ways of manufacturing have their Achilles heel in the surface finish, as they are a long way from achieving the roughness required by industry. Therefore, grinding continues to be a key process with a bright future within the fourth industrial revolution, and is probably the manufacturing technology with the highest added value.

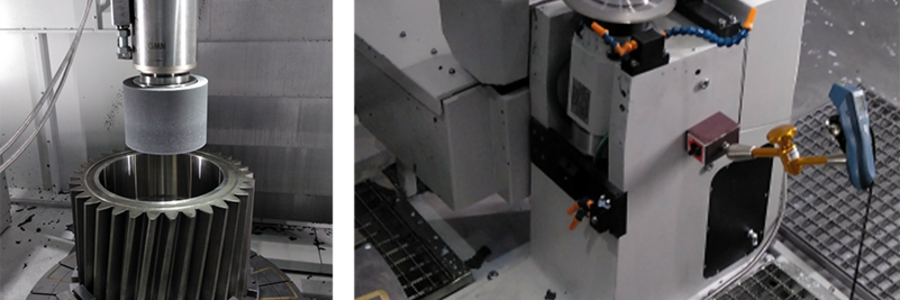

DANOBAT and IDEKO, with their extensive experience and recognised international prestige in grinding processes and in the resolution of problems caused by vibration, are working on the TWINGRIND project for developing an intelligent detection, measuring and grinding solution through the new possibilities offered by information and communication technologies (ICT).

The main challenge of this project is the attainment of surface finishes necessary on critical components that have relative rolling and sliding movement. Specifically, it seeks higher operating efficiency, an increase in the useful life of these components, a reduction in friction and a decrease of vibrations and noise in the grinding processes of high responsibility parts, with its consequent positive impact on climate change, transport sustainability and resource efficiency.

For all these reasons, the main project result consists of the development and incorporation of technologies in grinding machines for the elimination or minimisation of micro and submicrometric errors that make the attainment of the required surface finishes impossible. Specifically, it proposes attaining a solution for the automatic detection of error sources, the prediction of the form and magnitude of the submicrometric error and the development and implementation of multi-objective techniques to eliminate or minimise these errors