Own development model for Integrated Management of Technological Innovation.

Responsive and reconfigurable MaaS platform for large-scale and complex-shaped part manufacturing

Bulky part manufacturers accessibility to auxiliary equipment for workpiece setup, handling, processing and modelling is cumbersome and currently based on word of mouth, leading to rigid supply chains and a lack of flexibility to find alternative production paths.

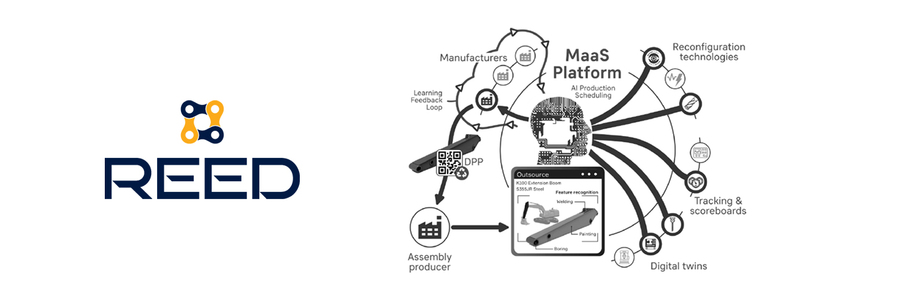

REED project addresses the servitisation of productive resources to achieve a more reliable, flexible, responsive and circular decentralized production of small batches of large and complex parts in the form of a MaaS platform. Manufacturing as a Service (MaaS) is a distributed system of production in which resources (including data and software) are offered as services, allowing manufacturers to access distributed providers to implement their manufacturing processes.

The main objective of REED project will be the development of a Manufacturing as a Service (MaaS) platform that will provide the enabling technologies, equipment and services for the manufacturing of bulky parts of the capital goods sector, assuring the quality of the produced components while maximising productivity and minimising environmental impact. The REED platform will redefine the B2B relationships through a networked digital productive model.

IDEKO will lead the asset servitisation task through the MaaS platform, providing machine and process modelling as well as process enhancement technologies. On the other hand, it will deal with the production data management and use in the platform, developing universal connectors among the various production support services and leveraging this data to improve the intelligence of the platform. Finally, IDEKO will also lead the industrial demonstration of the use of the developed platform in tree different industrial scenarios: a yellow goods manufacturer and two subcontractors dealing with large components from the energy and the machinery components sectors.