Own development model for Integrated Management of Technological Innovation.

Intelligent manufacturing systems for highly complex metal part

With a view to further developing innovative manufacturing technologies, the technology centre IDEKO-IK4 is actively involved in a research project, in the framework of the Challenges-Collaboration 2015 program of the Spanish Government, which pursues to obtain an advanced system to manufacture high added value metal parts.

The project is funded to the amount of €1,167,008, and is backed by the Ministry of Economy and Competitiveness (MINECO) and the European Regional Development Fund(ERDF) through the Challenges-Collaboration 2015 Program.

The LASMEC initiative, headed by the Basque machine tool manufacturer Soraluce , aims to develop an intelligent system that selects the most suitable production mechanism for metal parts with a complex geometry from laser direct manufacturing, machining or a combination of the two.

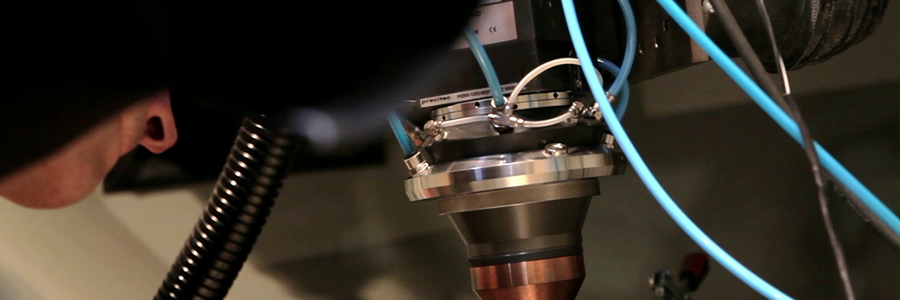

The unit consists of a recharging head, enriched CAD/CAM simulation software and dimensional control on a prototype.

Finally, the correct operation of the system will be validated by manufacturing a component defined by CETEC.

The role of IK4-IDEKO is to design and build a system for the hybrid manufacture of metal components, optimally combining the machining and cladding processes in collaboration with Soraluce, as well as to design a cladding head in collaboration with AIMEN.