Own development model for Integrated Management of Technological Innovation.

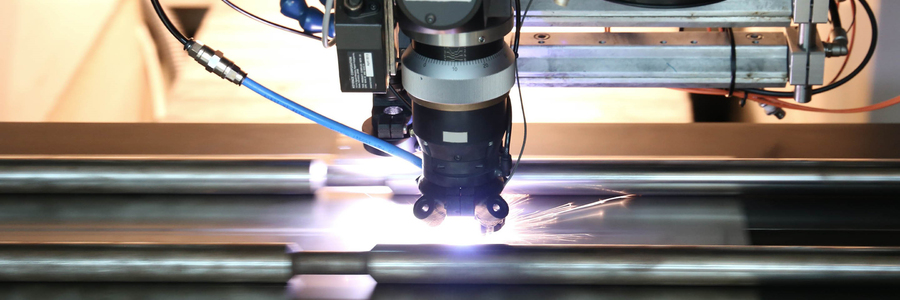

Extremely high-speed laser processes for sustainable and flexible manufacturing

The LASERWAY project aims to transform industrial manufacturing by developing high-speed, flexible and sustainable laser processes. This initiative seeks to replace traditional and polluting methods with advanced technologies that reduce CO₂ emissions, increase productivity and promote a more resilient European industry. LASERWAY focuses on three key applications: laser micro-drilling, laser blanking, and Extreme High-Speed Laser Application (EHLA) deposition. These processes, selected for their high potential, face technical challenges related to photonics, machine dynamics, and programming, which the project addresses with innovative solutions to enhance competitiveness and sustainability in manufacturing.

IDEKO plays a central role in LASERWAY as the general coordinator, ensuring the project"s technical and administrative management. Its contribution includes leading the design of innovative hardware and software solutions for high-speed laser applications, developing machine structures that combine high acceleration with precision and stability. IDEKO also oversees optomechanical integration and validates advancements in motion control and synchronization in applications such as coil-fed laser cutting. Additionally, IDEKO is responsible for developing high-speed laser cutting prototypes, enabling the validation of developed technologies in real industrial conditions, ensuring their effective transfer to the industry.

One of LASERWAY"s main challenges is the need to increase the speed of laser processes while maintaining high standards of precision and quality. Additionally, it is essential to design high-dynamic machines capable of withstanding extreme accelerations without compromising stability. The project also seeks to overcome specific limitations in applications like micro-drilling and EHLA, which currently restrict their industrial implementation. Another key challenge is the integration of advanced digital technologies and sustainable practices in industrial production lines, ensuring that processes are both efficient and environmentally friendly.

LASERWAY aims to revolutionize industrial manufacturing by replacing obsolete methods with high-speed, flexible laser technology, offering a sustainable alternative that reduces CO₂ emissions. The project seeks to double the productivity of laser processes while ensuring precise photon distribution. Focused on three main applications—laser micro-drilling, laser blanking, and Extreme High-Speed Laser Application (EHLA)—LASERWAY addresses challenges in photonics, machine dynamics, and programming. The objective is to achieve unprecedented productivity gains in laser processing and promote sustainable manufacturing across Europe. These advances are designed to transform strategic sectors such as automotive, aerospace, and water filtration, facilitating the transfer of these innovations to the industrial environment.

LASERWAY will develop advanced laser technologies organized into three modules, enabling the creation of a machine and process capable of operating at extremely high speeds while ensuring precise photon delivery at the right place and time. These innovations will support the implementation of flexible and sustainable production practices, paving the way for the replacement of conventional industrial applications. By achieving these objectives, LASERWAY aims to double productivity in laser blanking, laser micro-drilling, and EHLA applications, while improving precision and efficiency. Additionally, the project anticipates significant reductions in energy consumption and CO₂ emissions compared to traditional methods, driving a more sustainable and resilient industrial.