Own development model for Integrated Management of Technological Innovation.

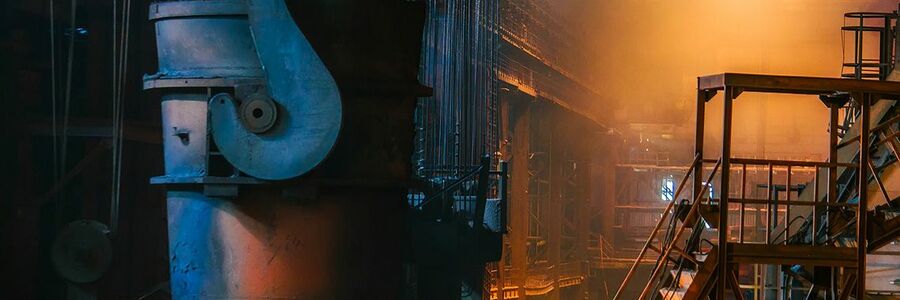

Digital technology to bring Industry 4.0 to the casting sector

The GALDA 4.0 project seeks to advance towards the new paradigm of advanced manufacturing for the manufacturing of sand moulds used for casting of metal parts.

The industry of cast metal parts manufacturing requires the use of moulds made with sand. Intermediate wooden and polystyrene models are currently used for its manufacture, a solution that not only is expensive but also generates waste material and emits polluting gases.

With the aim of moving towards a manufacturing process that does not require the use of wooden and polystyrene intermediate models, the GALDA 4.0 project managers are faced with the challenge of developing a technology chain that integrates the concepts of manufacturing 4.0 in the metal casting industry for non-serial parts.

To achieve this, machining a compacted sand block will be used to make the moulds.

The development of this solution will be done using a robot, which uses CNC programs and special tools for the machining of the highly abrasive sand. The robot will be in charge of sculpting the mould by machining the compacted sand block.

This project pursues different results, including the reduction of time spent on the process and material consumption, as well as cost savings. In addition, it also seeks to minimise waste emissions and produce superior quality parts. Another advantages of this project is the possibility to include a pre-mould check to reduce the risk of faulty casting.