Own development model for Integrated Management of Technological Innovation.

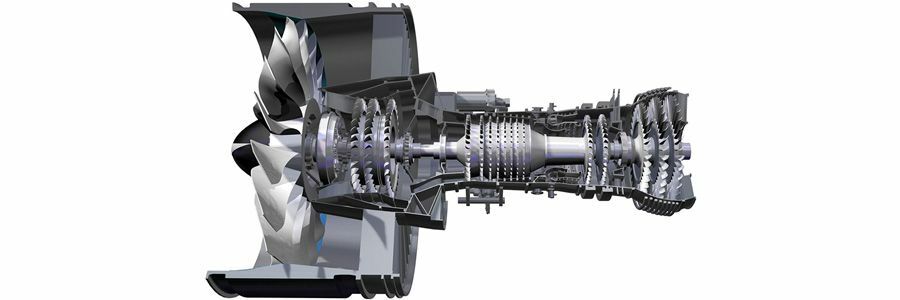

Integrated Zero Defect Manufacturing solution for high value adding multi-stage manufacturing systems

The global manufacturing scenario is continuously posing new requirements on production system adaptability. Increasing volatility in the local economies, shortening product life cycles, increasing degree of product customization, call for production systems that comply with these changing demands in all their basic functions, including quality and production control. ForZDM will develop an innovative Zero Defect Manufacturing methodology for reducing the number of defects and optimize production.

This project will be part of the 4ZDM cluster

Manufacturing companies face the challenge of delivering high quality products of increasing complexity, with limited use and waste of resources. "Zero Defect Manufacturing” (ZDM) is a recent paradigm aiming at going beyond traditional six-sigma approaches. The aim of the ForZDM project is to develop and demonstrate tools to support the rapid deployment of ZDM solutions in the industry and to design more competitive and robust multi-stage manufacturing systems.

The aim of the ForZDM project is to develop and demonstrate tools to support the rapid deployment of ZDM solutions in the industry and design more competitive and robust multi-stage manufacturing systems.

The ForZDM methodology expands current single process boundaries towards a production line perspective, which allows to contrast defects before, during and after their generation through diagnosis, preventive and corrective mechanisms, applied with real-time, medium term and long term control actions.