Own development model for Integrated Management of Technological Innovation.

Smart Inspection for a Zero Defect Manufacturing (ZDM)

The CONAN project faces the challenge of producing optimal quality components that have excellent qualities for competing on international markets. To meet this objective, the project hinges on two performance levels.

On the one hand, the optimisation of the manufacturing processes through the implementation of advanced simulation models. On the other, the implementation of digital inspection systems for the early detection of defects in the parts.

Both levels converge into an integrated zero defect manufacturing solution that will be applied to five different industrial cases that reflect the reality of the Basque manufacturing industry.

The objective of Zero Defect Manufacturing (ZDM) is to deploy advanced tools and high added-value solutions in order to achieve excellence in production.

Specifically, the aim of the project is to design a new integrated quality control solution that allows the efficiency and competitiveness of the manufacturing processes to be increased through the improvement of the final quality of the parts.

IK4-IDEKO will provide knowledge and experience in advanced manufacturing for the generation of the CONAN integrated Zero Defect Manufacturing solution.

Firstly, it tackles the development of machining models applicable in the plant that provide intelligence to the production processes. This covers the first performance level of the solution.

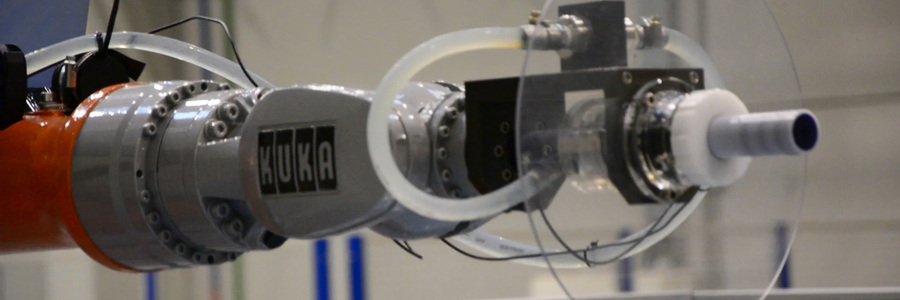

Secondly, IK4-IDEKO will develop inspection systems based on ultrasonics and induced currents that allow defects to be detected automatically and digitally. As a result, the second level of the solution will be obtained.

Both levels will be connected giving rise to the global platform.