Own development model for Integrated Management of Technological Innovation.

Manufacturing processes for bio-based fibre-reinforced composite parts for structural applications

Composites currently rely heavily on carbon and glass fibers for reinforcement. However, the utilization of synthetic composites poses numerous challenges, including recycling difficulties, dependence on third-party countries, and environmental impacts. A substantial 80% of these fibers are manufactured outside of Europe, and roughly half of the remaining 20% is produced under foreign licenses, contributing to a significant reliance on other nations.

Bio-composites, incorporating natural fibers, with hemp and flax being the most prevalent, present a promising solution to reduce this dependence. Hemp cultivation is widespread across Europe, yielding over 150,000 tons annually. Similarly, flax production is significant, with 80% of the required flax in Europe sourced locally. By leveraging natural fibers, the reliance on imported materials can be substantially diminished, thereby bolstering the autonomy of the European composites industry.

Nevertheless, the current application of bio-composites is confined to less critical uses without significant mechanical performance requirements. Natural fibers, as bio-based materials, exhibit greater variability in dimensions, weight, appearance compared to regular, smooth, and solid synthetic fibers. This disparity in properties necessitates a deeper understanding to tailor weight-to-performance systems and adapt manufacturing processes accordingly.

Its main goal is to develop manufacturing processes to boost the use of bio-based fiber-reinforced composites for structural applications.

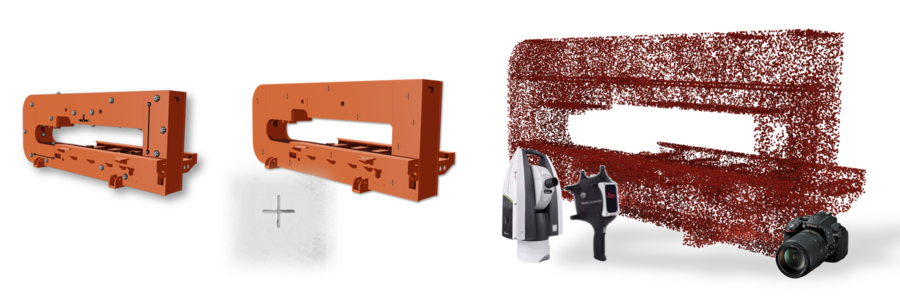

IDEKO will perform 3D measurements to assist in the development of material models. The primary technology employed will be 3D absolute scanning, using the laser triangulation principle to generate a dense cloud of points. The second technology involves 3D scanning through photogrammetry, enabling fast measurement of all the details of the shape, including inner and hard-to-reach surfaces.

The 3D scanning of the part will be critical input for achieving an accurate material modelling process. These inputs play a crucial role in creating a detailed virtual representation of the part, subsequently updating CAD models. Additionally, 3D measurement technologies will be synergized with robotic draping and grippers to obtain precise models, thereby enhancing the accuracy of the draping process.

The BioStruct project aims to achieve several outcomes, such as increased productivity, ensuring consistently high quality in high-precision manufacturing, promoting strategic independence for the EU manufacturing industry, and lowering greenhouse gas emissions. By concentrating on boat building and wind energy, the project directly targets 25% of the market, and potential applications in sports equipment and automotive are anticipated to boost the share to 45%. With the projected growth of the bio-composites market, the consortium envisions a market potential of around €100 million by 2030, leading to a significant reduction in greenhouse gases, estimated at 2.5 to 4.3 million tons of CO2 per year.

The project anticipates achieving predictable properties and consistent quality through enhanced accuracy and additional control loops in the manufacturing process.