Own development model for Integrated Management of Technological Innovation.

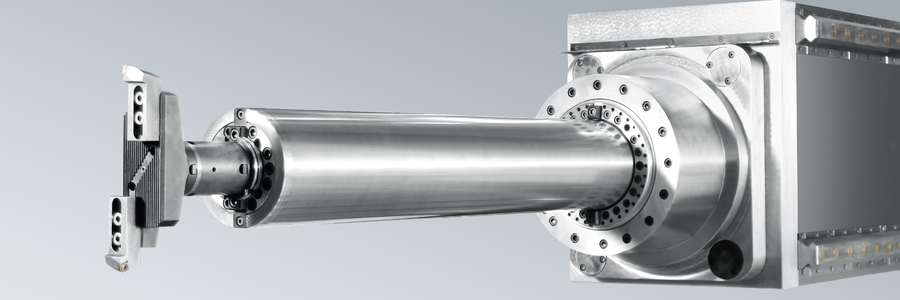

Development of a shock-absorbing and fretting-resistant quill

SORALUCE pursues to manufacture a new quill model, thus doing away with all problems inherent to current quill models with bearings. This model provides improvements superior to those offered by hydrostatic quills with a cost not exceeding 10% of the current quill concept with bearings. The objectives are the following:

• To increase the dynamic stiffness of the full extension of the quill without the use of steady rests or external elements, especially for large extensions, where the dynamic stiffness is expected to increase by around 100%.

• To minimise the thermal expansions of the quill by developing a compensation system for thermal expansion that exceeds the current compensation system for thermal expansion by some 20%.

• To increase maximum achievable rotation speed by 10%.

• To completely cancel the fretting phenomenon.

• Design of a shock absorber integrated into a modular quill for increased dynamic stiffness.

• Design of a linear guidance system with a fretting-free quill.

• New lubrication system, bearing assembly and quill guiding to increase rotation speed and avoid excessive heating, seizure and mechanical element failure.

• On-machine compensation system for thermal expansion on quills.

The result of the AQUILLES project is a prototype of a quill with high cutting capacity, precision and fretting resistance.