Own development model for Integrated Management of Technological Innovation.

Currently, quality controls used in the environment of micro-manufacturing are taken from macro-manufacturing.

Currently, quality controls used in the environment of micro-manufacturing are taken from macro-manufacturing, based on geometric controls after obtaining the components. This entails that a lot of time passes between error generation and detection, possibly causing a large number of defective parts or an unnecessary long processing time. Furthermore, this method does not provide direct information about the error generation, preventing rapid action on the cause.

Micro-manufacturing processes require "zero defect" approaches, both in mass-manufacturing and in single-unit production environments. For this reason, it is necessary to extend the validation of the end product to focussing on process monitoring. This focus should apply to the monitoring of all process parameters and to aspects of raw material control or final handling of the manufactured parts. The information obtained should be processed in real time and be used as fresh input to predict the possible errors and to, thus, take action to prevent this error. With this approach, the MIDEMMA project aims to provide a comprehensive solution for the implementation of "zero defects" methodologies in micro-manufacturing processes on a European level.

MIDEMMA has addressed the resolution of such errors/defects.

MIDEMMA has addressed the resolution of such errors/defects, acting in fields such as metrology and handling, process monitoring, adaptive control systems or support systems for decision-making based on process data.

All research work and technological development have resulted in demonstrators of which we have high expectations.

All research work and technological development have resulted in demonstrators of which we have high expectations for future exploitation and market possibilities for the industrial operators that form part of the project.

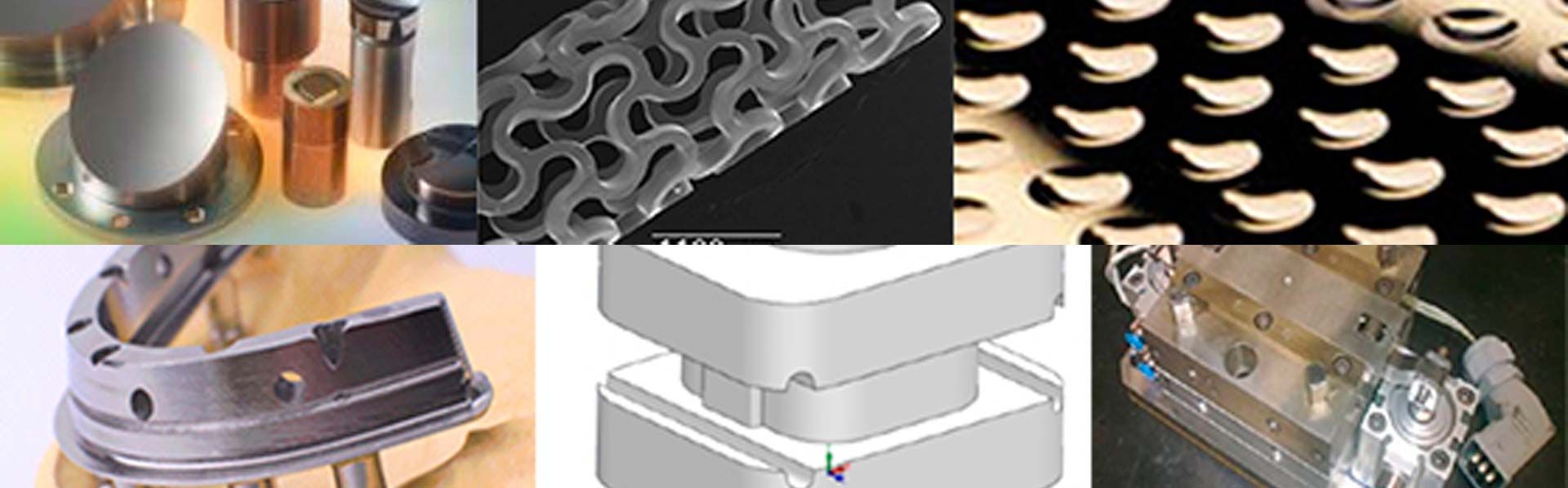

The work of Ideko has focused on the elimination of defects in processes for the manufacture of dental prostheses, mainly used in Createch-Medical, a company participating in the project. The main developments can be separated into two different sections:

•Development of part measurement and monitoring systems (on and outside the machine).

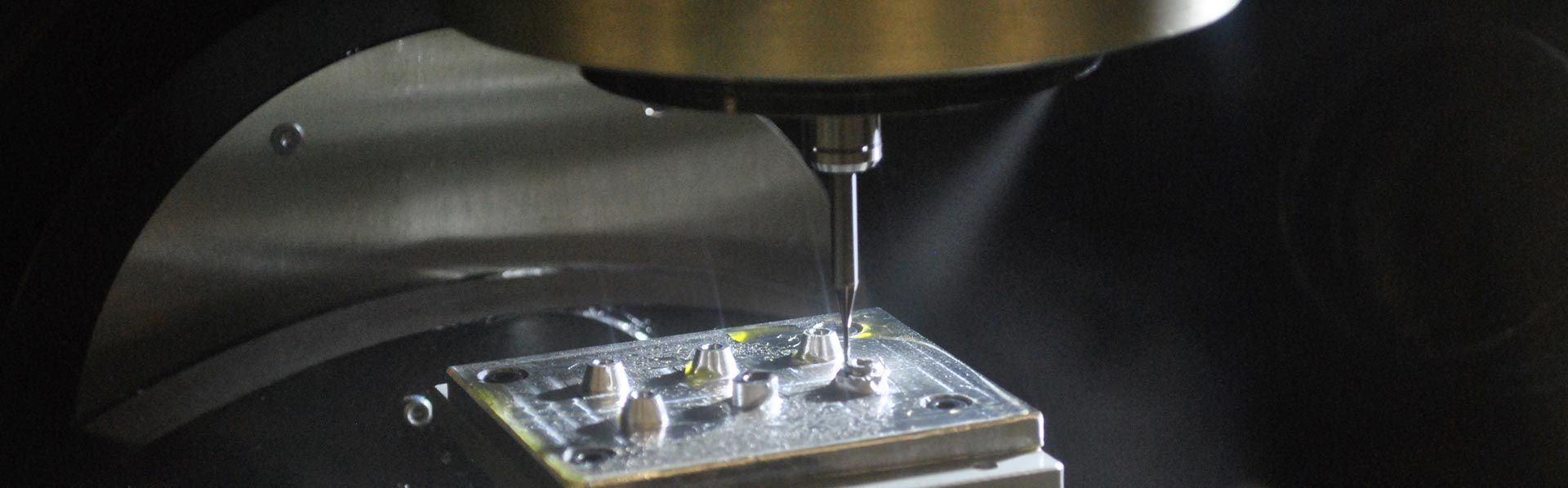

•Development of methodologies (based on monitoring, simulation and process control) for eliminating defects in precision milling and laser ablation processes.

The Machining and production systems line, along with the Design and mechanical precision line participated in the project in research and technological development which has resulted in demonstrators of which we have high expectations for future exploitation and market possibilities for the industrial operators that form part of the project.

During the MIDEMMA project, mainly ultraprecision laboratory equipment has been employed. Specifically, developments in regard to workpiece measuring relied on the confocal microscope Sensofar PLµ Neox; while development related to the manufacturing processes were carried out on the precision milling machine IK-mill and on the IK-Laser picoseconds laser ablation unit.