Own development model for Integrated Management of Technological Innovation.

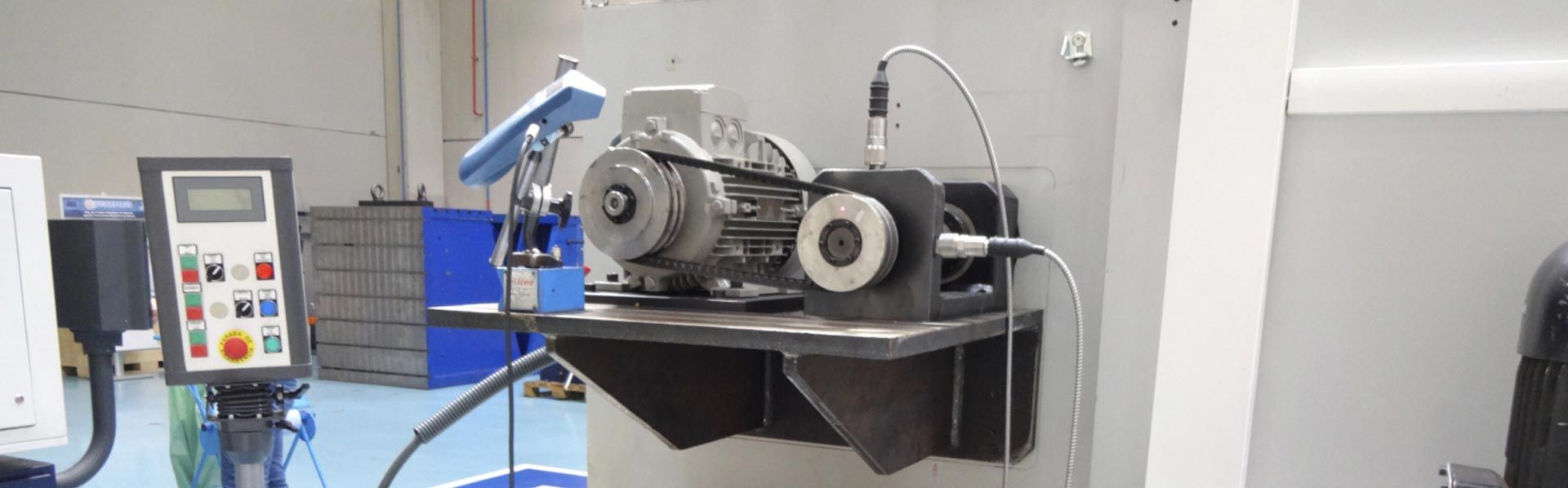

More accurate machine, reducing vibrations.

Companies need to count on more and more accurate, economical and efficient equipment which allow them to make products with high standards of quality. To achieve this objective, reduce machine vibrations as much as possible, is the key.

The apparition of vibrations is one of the principal problem which face the industry and supposes a considerable limitation of its productivity, due to a no-desired functioning of equipment that reduces machines and tools life.

So far, the diagnostic of vibration causes and the development of solution to eradicate them have been possible through the use of large equipment and highly skilled personnel, with a very high economic cost derived.

The computer can acquire data from different kind of sensors

Data analysis and the use of advanced technologies allow us to offer solutions to a recurring problem from a holistic perspective, which is a major burden for production processes.

In this context, IDEKO has developed ikDAS, a portable platform for signal acquisition with four operating modules that allow the frequency analysis of signals and the obtaining of frequency response function of key components such as structural machine parts.

The computer can acquire data from different kind of sensors, either voltage as excitation required, can be selected by means of a data acquisition software, and so later off-line, to visualize the temporal evolution of signals and perform relevant spectral analysis.

The user interface is structured through interactive dialogues that allow a quick and simple operation, so that it is not required to have extensive technical knowledge to be used.

4 modules in diagnosis and vibration analysis.

Researchers at IDEKO have determined four diagnostic areas related to the generation of vibrations on which to focus the action of ikDAS to improve the efficiency of the equipment.

The device achieves signals recording and process signals of vibrations to diagnose possible problems.

The 4 designed modules are embedded within the package, which is composed of a computer and has a simple and intuitive interface, manageable by any operator after a brief training without specific knowledge.

The potential of data acquisition and analysis, along with the portability and user-friendly interface, make ikDAS an ideal tool for workshops on tasks such as maintenance, assembly, machine preparation, machining problem resolution, etc.

In addition, its scope extends to the fields of R&D and professional training.

ikDAS is an advanced tool adapted to the requirements of the industrial manufacturing sector to ensure the quality of processes as well as a tool for training in the field of education.

The knowledge and experience of IDEKO in the latest technologies applied to manufacturing have contributed to the design of this platform that enables to solve efficiently an endemic problem of machine with rotary dynamics. The development has been possible thanks to the work of the Dynamics and Control research line, which has extensive experience in the characterization and optimization of dynamic behaviour of machines and processes. Professionals in this department are faced with the decision of the vibrational problems in all types of industrial machinery from two different and complementary approaches: on one hand the dynamic design of machines and drives and on the other hand diagnosis and subsequent implementation of solutions development itself that eliminate chatter and vibration in various machining processes. Dynamics and Control research line is a multi-disciplinary group of recognised prestige in the international field of science and technology.

IDEKO has advanced facilities that place us at the forefront in our specialization at national and international level. To support research activities carried out in the field of inspection and measurement, will open this year a new laboratory equipped with the latest technology in non-destructive testing.