Own development model for Integrated Management of Technological Innovation.

Currently, chatter is considered one of the greatest challenges to be overcome to increase production in the machine tool sector.

Currently, chatter is considered one of the greatest challenges to be overcome to increase production in the machine tool sector. Chatter causes unacceptable surface finishes, tool breakage and a reduced life cycle of different mechanical parts of the machine.

The main challenge of this project is to reduce the risk of chatter during the machining process and consequently to improve the cutting capacity of the machine.

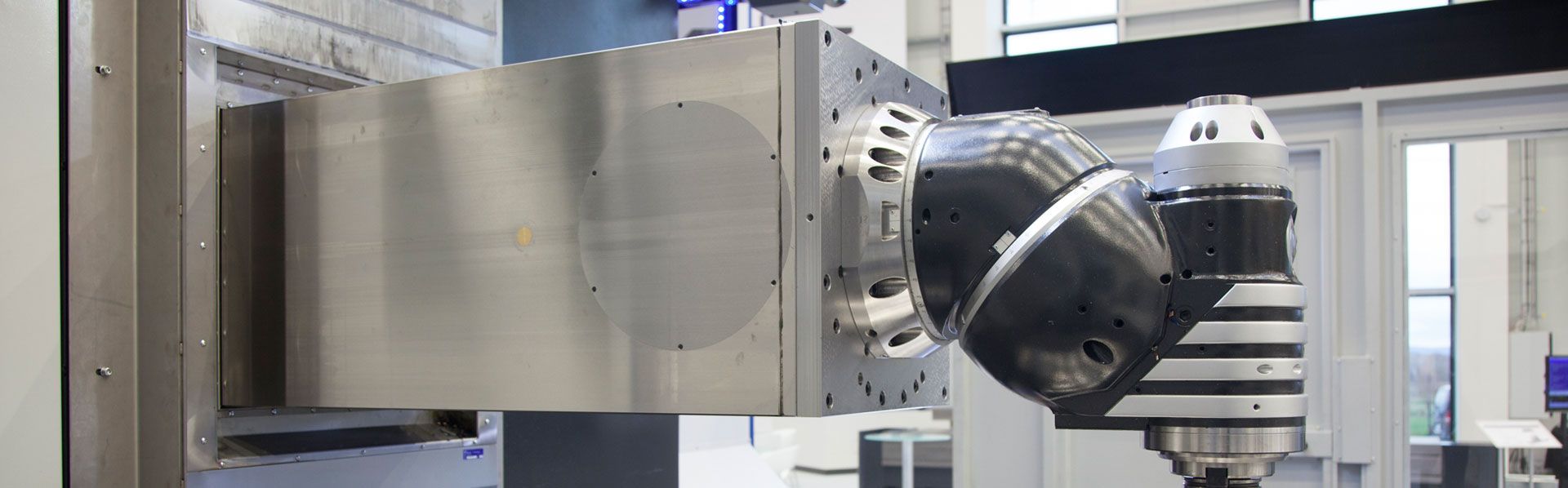

The stability of a machining process goes hand in hand with the dynamic rigidity of the machine. On machines fitted with a mobile ram, this rigidity can vary significantly depending on the position of the workpiece. The DAS system, however, overcomes these drawbacks and secures an effective performance during the machining process.

The key lies in that the system reacts actively according to the varying situation of the machining process, and thus better use of the cutting capacity of the machine is made, regardless of the position of workpiece.

With the aim of meeting the challenge posed by modern industry, a device capable of actively increasing the dynamic rigidity of the machine has been developed which increases the cutting capacity and reduces the risk of instability.

With the aim of meeting the challenge posed by modern industry, a device capable of actively increasing the dynamic rigidity of the machine has been developed which increases the cutting capacity and reduces the risk of instability caused by chatter during the machining process.

The DAS system is specially designed to eliminate structural vibrations of the machine. This unique system is fitted with sensors that measure vibration and generates counter oscillations in real time using special actuators fitted on the ram to compensate for the vibrations during the machining process.

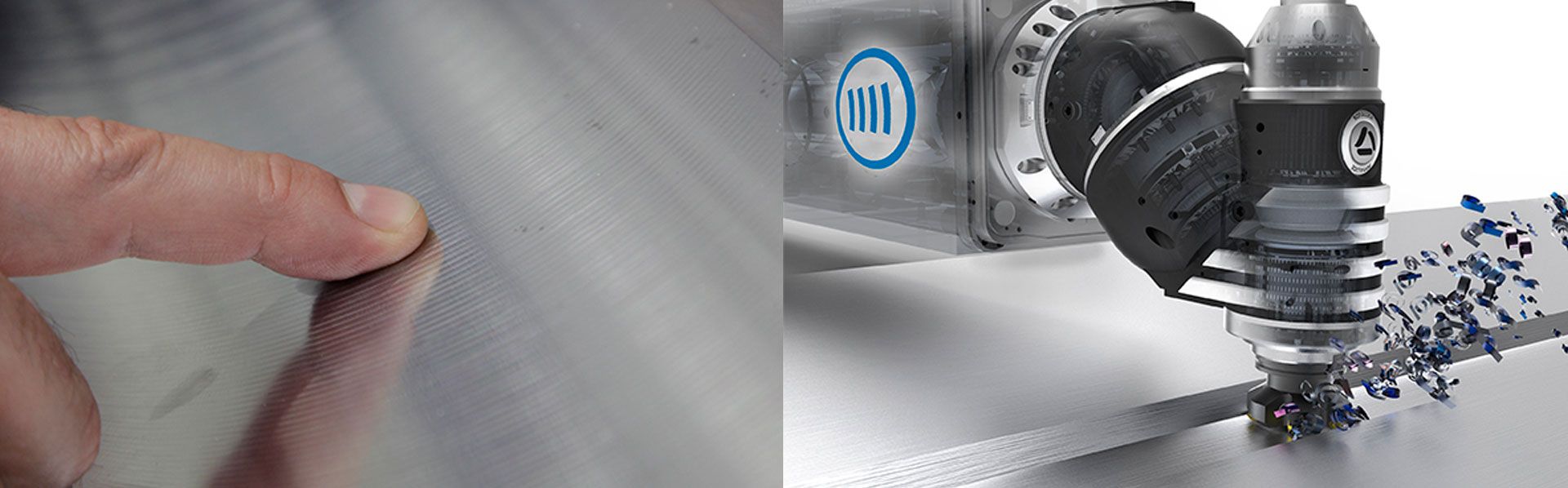

The DAS systems increases the cutting capacity of the machine.

The DAS systems increases the cutting capacity of the machine, improves surface quality and reduces the risk of tool breakage, and at the same time lengthens its life cycle in extreme cutting conditions.

The DAS system overcomes the physical barriers of machining and yields an increase of machining performance of some 300% by suppressing chatter.

It is the first and only system for chatter suppression on the market, standard fitted on the machine head. At present, the equipment is being patented.

The system has been put to the test in all types of machining processes, such as on heads of presses, polar parts of motors or moulds. On all processes, a reduction of up to 45% in machining times was achieved.

IK4-IDEKO"s knowledge and experience of the latest technologies applied in manufacturing have resulted in the design of a platform that quickly and efficiently tackles this widespread problem on machinery used in the machining sector. The development has been possible thanks to the work carried out by engineers of the "Dynamic and Control" research line which has wide experience in the characterisation and optimisation of the dynamic behaviour of machines and processes. Professionals from this research line address the resolution of vibration problems in all types of industrial machinery from two different and complementary approaches: on the one hand they consider the dynamic design of machines and drives, and on the other the diagnosis and subsequent implementation of specific development solutions that eliminate chatter and vibrations in various machining processes. The Dynamics and Control research line make up a multi-disciplinary group of recognised prestige in the international field of science and technology.

The Department of Dynamics and Control has an experience of more than 10 years in the field of the vibration damping. In this period, this department has participated and led international projects aimed at developing both active and passive damping systems. SMART TOOL, CHAMALEON and DYNEXPERTS are some examples of the above. As a result of the projects mentioned above, an example is the development of multiple solutions to address the problem of chatter, such as for example active damping. These active dampers have created solutions ranging from one to several degrees of freedom that have been designed specifically for fitting on the ram or on the head. Proof of this is the patented head damping unit (P201330810).