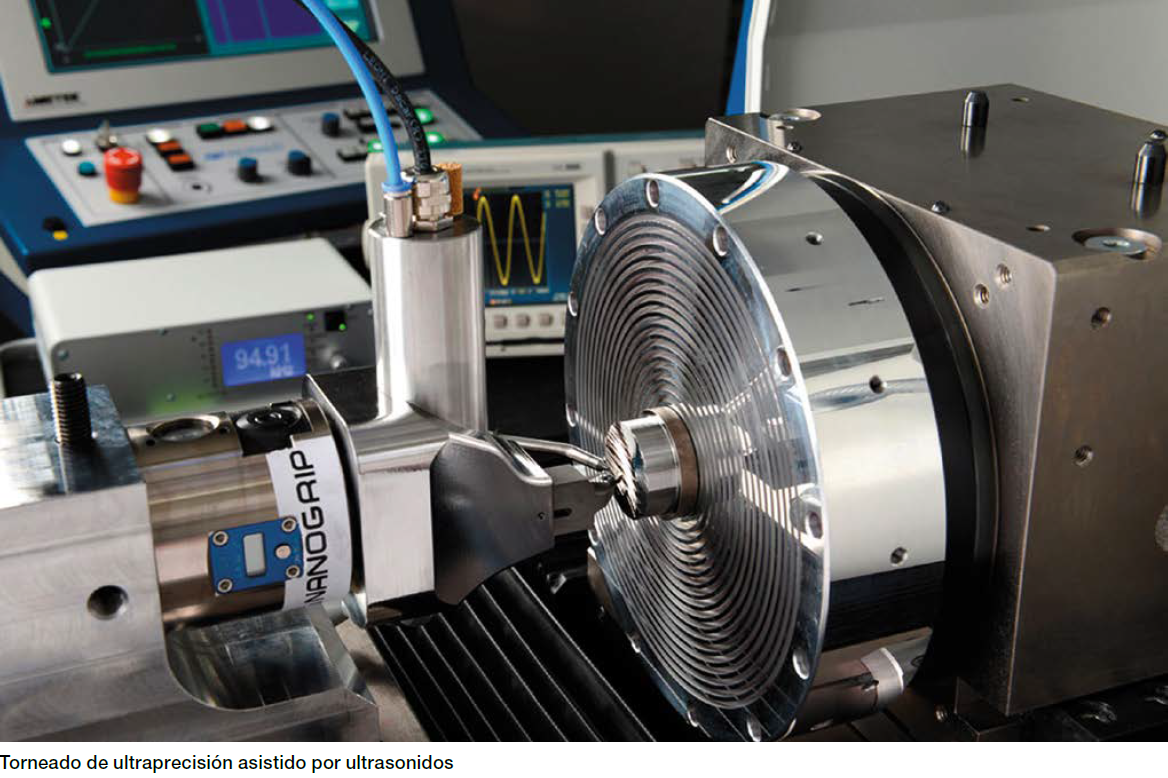

IK4-IDEKO is

presenting a project that will optimise productivity and efficiency of the

turning of low machineability materials, common in markets such as

aeronautical.

Turning is one of the most widely used stock removal processes in industry,

especially used for ferrous metal materials. However, in recent years, the

application of exotic materials such as aeronautical alloys, has led to turning

conditions becoming stricter and the existing techniques have to be optimised

or new procedures developed for their machining.

As an example,

in the aeronautical sector, the critical parts are the engine compressors and

turbines which are made up of materials such as titanium alloys and

nickel-based super alloys such as Inconel 718. These critical parts are made of

low machineability materials, but are subject to strict requirements and

standards. It is essential to control the process so that production costs do

not escalate and to offer a quality and competitive product.

See whole article