Last news about IDEKO.

Next 26 and 27 June, IK4-IDEKO together with IK4-TEKNIKER and another 10 partners will present the developments produced in the DYNXPERTS European project which have resulted in three patents and two products for the Machine Tool sector.

Led by IK4-IDEKO, the DYNXPERTS project - "Plug-and-Produce components for Manufacturing systems with Optimal Dynamic Performance" has been a strategic challenge for its 12 partners, opening doors to the creation of manufacturing systems with easily implemented devices capable of adapting to the changing conditions of the process.

This project is being carried out within IK4-IDEKO's "Dynamic and Control" research line centred on the characterisation and optimisation of the dynamic behaviour of machines and processes.

Improvement in process productivity and quality

The main result of this project has been the development of a series of "plug-and-produce" components for improving process productivity and quality in the production chain, specifically on machine tools, a key component in production processes.

Overcoming limitations

Currently machine tools are complex structures full of sensors and actuators. However, the measurement points and drive controls in these systems are generally outside the cutting zone and frequently the bandwidth is not sufficiently wide to prevent vibrations and ensure good dynamic behaviour. The DYNXPERTS project has overcome these limitations with the introduction of actuators and sensors installed as close as possible to the machining point.

Easy installation and more complex operations

The developed "plug-and-produce" components have built-in sensors, advanced actuators, easy-to-use software and, in several applications, intelligent materials. Smooth installation on machine tools allows their functionality and productivity to be increased, making them capable of tackling more complex operations and at the same time reducing the risk of defects and accidents.

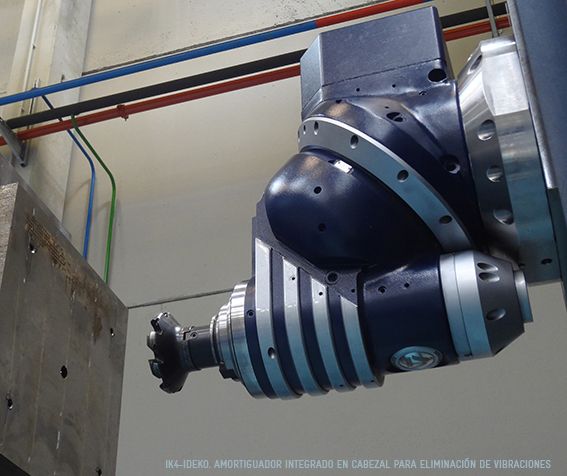

With this aim in mind, the DYNXPERTS project has developed a new generation of adaptive components including two mechatronic heads, one for processes with high torque demands and a second high-speed head based on magnetic levitation.

The project results have given rise to three patents and two final products ready to be marketed. Furthermore, two end users are evaluating developments from the project in industrial conditions.

Thanks to the excellent work carried out by the project partners, three inventions have been patented. One is a new mechatronic head for milling, with self-tuneable damper based on eddy currents and a clamping system for complex shapes based on magnetorheological fluids. These elements are easily coupled to the original machine to eliminate or dampen vibrations produced in machine-tools during machining processes using an active damping strategy.

Also derived from this research work have been two new products already available in the products catalogue. The first is a MICA actuator, which generates a greater force in a smaller volume compared to those on the market. The second result is a UC65 digital controller designed to control complex mechatronic systems.

The Technological Centres (IK4-IDEKO, IK4-TEKNIKER, RWTH, CNRS, BME, UPV-EHU) have developed cutting edge technologies such as active dampers, adaptive controls, magnetic levitation, stability models, wireless communication and energy storage that have been incorporated into the machine. For their part, the machine tool manufacturers SORALUCE and FIDIA were responsible for conveying the needs of the industry to the other partners and have incorporated the developed components into their machines. Lastly, the component manufacturers CEDRAT, PLANLAUF, Dr. MATZAT, and GOIALDE have built a new generation of adaptive components.

Twelve partners from 5 European countries have participated in the DYNXPERTS project, who will get together on the 26 and 27 at IK4-IDEKO to present all their developments to the European Commission. The consortium has a balanced participation of companies, research centres and universities and has a budget of 5.1 million Euros, with EU funding of 3.5 million Euros.

More information on the project at www.dynxperts.eu

The demonstrator's videos can be seen both on the YouTube channel http://www.youtube.com/user/dynxperts and on the channel