Last news about IDEKO.

On the 25th and 26th of October celebrated the kick off meeting of the European project MC-SUITE at IK4-IDEKO's failities.

IK4-IDEKO contributes with its knowledge in cyber-physical systems to apply the latest technologies to conventional industrial environments.

One of the main challenges facing Europe in the coming years is to introduce the manufacturing industry to information and communication technologies to ensure that their products remain competitive in global markets.

And, in this commitment to the Industry 4.0, the European Commission has placed its trust in the hands of the Basque technology centre. The results of the initiative will be put to the test in key sectors such as aeronautics, rail and automotive.

Some 12 entities and companies from 7 European countries are involved in the project, Activeeon, Aeromec, Cedrat Technologies, Diad Group, Fidia, Sintef, Tagueri, The University of Nottingham, Gamax, the Basque machine tool company Soraluce and the Mondragon University.

MC-SUITE, which seeks to transform conventional manufacturing environments to enhance competitiveness, optimise processes and reduce costs, forms part of the plan of action to support the industry "Factories of the Future" integrated in the Horizonte 2020 incentive program for innovation launched by the European Commission.

The project, recently approved by the European Commission, has an expected duration of 3 years and aims to use the possibilities offered by information and communication technology (ICT) and cutting edge techniques in advanced manufacturing to make manufacturing processes more efficient.

The results of the initiative will be put to the test in key sectors such as aeronautics, rail and automotive.

More specifically, the MC-SUITE seeks to develop a new generation of advanced tools for simulating industrial processes through the use of cutting-edge technology applied to functions such as data acquisition, monitoring and measuring of key physical aspects for manufacturing of the final product.

"MC-Suite aims to significantly reduce the gap that currently exists between virtual models, i.e. programmed manufacturing processes, and the actual process as performed in workshops and on production lines", says Xavier Beudaert, project coordinator in IK4-IDEKO.

The overall objective of the project is to enable manufacturing companies to compete effectively in a global market through technology transfer.

IK4-IDEKO's contribution

The technology centre, a benchmark in Advanced Manufacturing, will lead one of the modules of the project:

MC-Virtual. In this section, IK4-IDEKO will use its knowledge in advanced techniques of cutting processes and in dynamic effects causing chatter (vibrations produced during the machining process) to contribute to the design of tools in computer aided manufacturing.

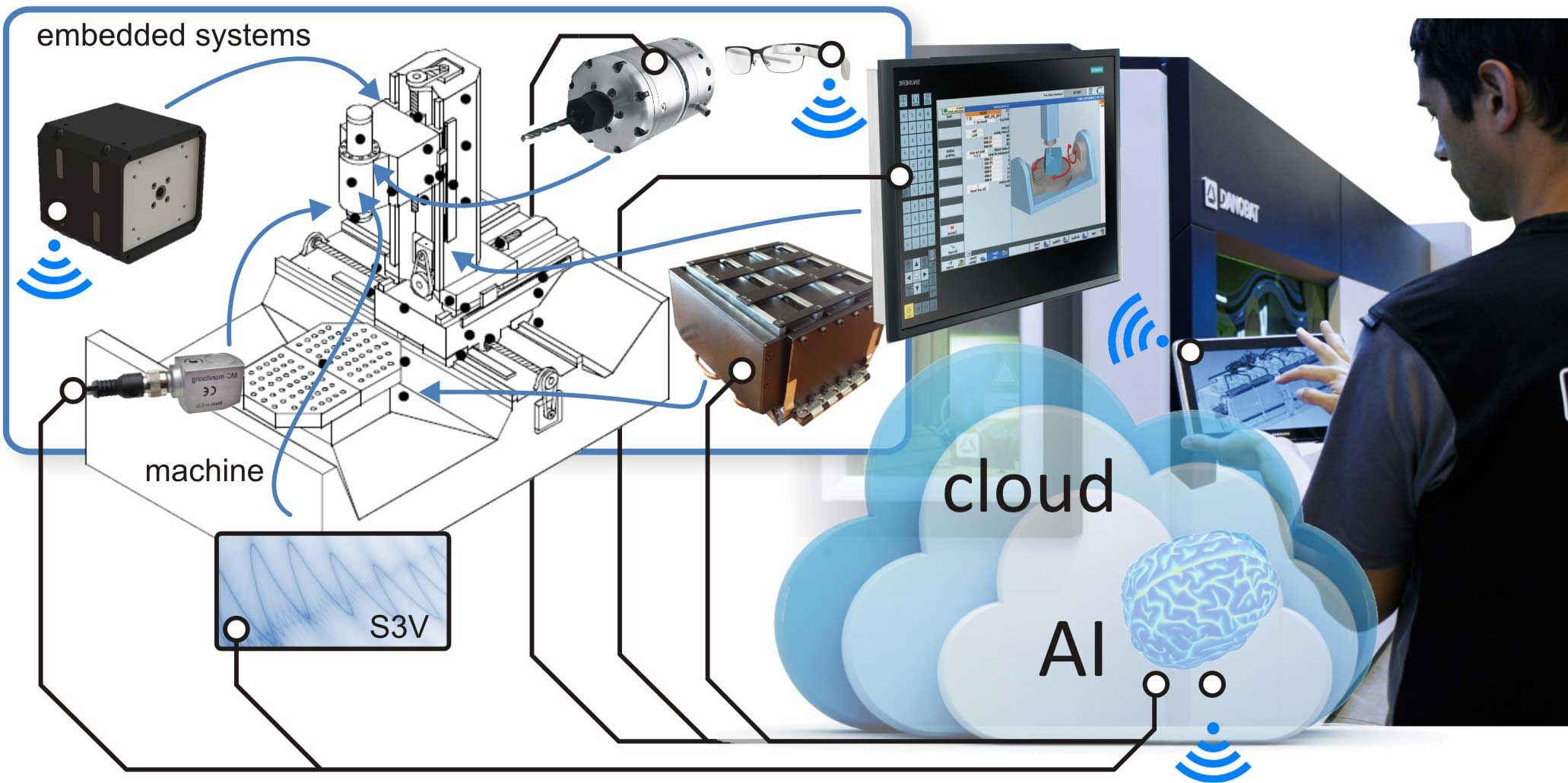

Furthermore, IK4-IDEKO will coordinate the section MC-CyPhy, aimed at transforming embedded systems for chatter suppression in cyber-physical systems capable of interacting with the environment to perform a self-diagnosis of the situation or of failures.

"Our contribution addresses the field of cyber-physical systems and advanced manufacturing techniques; we have a long-standing track record in both areas.

We also participate in process and machinery monitoring so that industry can offer new services to its customers" according to the expert.

A single project, six activity modules

The initiative is structured around various modules starting with MC-Virtual, a section aimed at the design of new technological tools that go beyond the current limits of computer-aided manufacturing (CAM) software with the objective of gaining an in-depth knowledge of the path, final quality of the part, cutting forces and process stability.

The second block, MC-Optim, focuses on the optimisation of the multi-objective machining process including productivity and quality parameters.

The MC-CyPhy module seeks to increase productivity through the use of different embedded systems connected to a virtual model and a monitoring system.

Fourthly, there is MC-Monitor, a system based on the storage of critical data in the cloud, such as signals from internal sensors of a machine, from embedded systems or data entered by operators.

The MC-Analytics module consists of creating a platform for processing information from the cloud aimed at predictive maintenance and productivity improvement.

And finally, MC-Bridge aims to be the link that serves to compare the result of the virtual model with the actual measurements obtained with the monitoring system.

The aim is to reduce both on-line and off-line discrepancies in order to improve the machining process and a simulation of this process.